![]()

| |

|

|

Founded in 1948, Corbitt has served the transportation industry in the automotive, railroad and trucking areas, as well as the general metalworking, defense, construction and industrial sectors for 50 years.

Permanent mold aluminum castings have several advantages over sand castings, according to Tom Rhoads, general manager.

Permanent molds offer a better surface finish for an improved appearance; a good grain structure permits greater strength characteristics and less porosity than sand castings; and tighter tolerances mean less allowance for required material to machine finish. This minimizes machining costs.

In the foundry area, Corbitt has three reverbatory furnaces. A Harrison (24" x 24") is used for core making. Molding equipment includes seven machines (four-18" x 24" Stahl, two-32" x 32" Hall, and one-48" x 62" Hall), four carrier-type machines and two large diameter vertical pour machines (for wheels, etc.).

In addition to the foundry, Corbitt has CNC machining capabilities for both ferrous and non-ferrous products: milling, boring, turning, drilling, reaming, tapping and broaching.

The machine shop is equipped with an Okuma 600 CNC horizontal machining center; a Mazak F11680 horizontal machine center; a Mori-Seiki DL 150Y Twin Spindle/Multi-Access Turning Center; a Mazak Micro- Center VMC; a Mazak Dyna- Turn 3L turning center; an Okuma 15 lathe (with bar feed); 17 automatic and engine lathes; two Amada automatic saws; drills and broaching machines, etc.

|

|

| Corbitt Manufacturing utilizes a Mori Seiki SL-300 CNC lathe with a 15" chuck and live tooling to enhance its precision machining capabilities. In addition, the company recently purchased an Okuma MC50VA vertical machining center. |

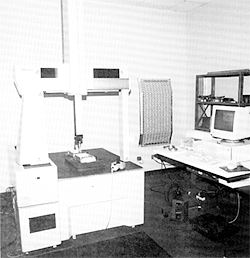

A Mitutoyo CMM-BRT 707 is used in the quality assurance department.

Other services include alu- minum heat treating using three 1,000-pound Solution furnaces and a 2,500-pound Dispatch Age oven.

Corbitt also does fabricating, assembly and testing.

"Complete fitting, welding, mechanical assembly, painting and testing are available to suit your quality standards," Rhoads said.

As published in Mid-America Commerce & Industry magazine