Dual Station Core Making Machine |

Gravity Tilt Pour Machine |

Reverberatory Furnace |

Heat Treating Furnace Operation |

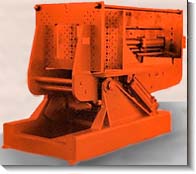

HALL #6H Tilt-Pour

Permanent Mold Casting Machine |

New "Solution

Furnace" |

Rotary Stainless

Steel Shot Blasting Machine |

|

Corbitt produces permanent mold aluminum castings. These

castings have the following advantages over sand castings:

![[Bullet]](images/bullet.gif)

|

Better surface finish for an improved

appearance |

![[Bullet]](images/bullet.gif)

|

Good grain structure permits better

strength characteristics and less porosity than sand

castings. |

![[Bullet]](images/bullet.gif)

|

Tighter tolerance than sand casting,

which means less allowance for required material to

machine finish. This minimizes machining cost. |

Permanent molding also has the capability to cast in

parts such as: studs, nuts, bushings, pipes, and any other

integral parts. Parts can range in size from 1lb to 75lb.

Foundry Equipment

|

|

Molding Equipment |

|

|

7-Tilt Pour Machines |

|

|

4-18"x24" Stahl |

|

|

2-32"x32" Hall |

|

|

1-42"x62" Hall |

|

|

4-Carrier Type Machines |

|

|

1-Large Diameter Vertical Pour Machine

|

Furnaces

![[Bullet]](images/bullet.gif)

|

3-Reverbatory |

![[Bullet]](images/bullet.gif)

|

1-Gas Crucible |

Core Machines

Aluminum Heat Treat Equipment

![[Bullet]](images/bullet.gif)

|

3-1,000lb. Solution Furnaces |

![[Bullet]](images/bullet.gif)

|

1-2,500lb. Dispatch Age Oven |

![[Bullet]](images/bullet.gif)

|

1-1500lb. Solution Furnace |

Finishing Equipment

![[Bullet]](images/bullet.gif)

|

Jet Wheelblast- Rotary Stainless Steel

Shot Blasting Machine |

Testing Equipment

![[Bullet]](images/bullet.gif)

|

Spectrometer- Arun Technologies 2000

|

![[Bullet]](images/bullet.gif)

|

Brinell Testing |

![[Bullet]](images/bullet.gif)

|

Tensile Test |

Cast Valve - 30" long |

Custom Casting for

Overhead Material Handling |

Cast Handles |

Gear Box |

|

![]()