![]()

Firm offers Aluminum Casting & Precision Machining

|

|

| A sample of Corbitt's work. |

Corbitt's foundry pours aluminum castings in the pound to 30- pound range out of five different aluminum/silicon alloys using permanent and semi-permanent molds.

The foundry is moving from the traditional batch process to a cellular manufacturing approach. "This will allow us to better accommodate large production runs," observed Chris McCafferty, foundry engineer. "Each cell will specialize in a certain size of castings and be self-contained. Only heat-treating will be centralized after the changes are implemented."

The company's customer focus is to work with customer's quality departments and engineers, from mold design through first article inspection, to create a casting that is manufacturing friendly. Lower manufacturing costs mean lower cost for customers. The ISO system allows continuous focus on process improvement.

|

|

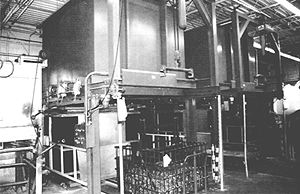

| Two

new heat-treating ovens recently installed in Corbitt's foundry area. |

In pursuing their philosophy of supplying a quality finished product, Corbitt has a fully equipped state- of-the-art CNC machine shop. Other equipment includes: manual lathes, welding machines, saws, mills and broaching machines. The company also provides fabrication, assembly and testing services. The quality control area monitors metal chemistry, density, hardness and tensile strength.

Corbitt Manufacturing Company can be contacted at: (314)773- 3046; Fax (314)773-0585; 5249 Northrup Avenue, St. Louis, Missouri 63110-2089.

As published in Mid-America Commerce & Industry magazine, June-July 2000